Semiconductor is widely used in all fields of society. Semiconductor industry is the national basic industry, the national lifeline industry, and China is a big country of semiconductor industry.

With the arrival of high-end technology such as artificial intelligence, semiconductor industry has become more and more important. Chip (integrated circuit) manufacturing technology is the highest level of micro-machining technology in the world. It is the commanding point of high-tech competition in all countries in the world. Chip manufacturing technology greatly reflects the high-tech strength of a country. Semiconductor material is the electronic material of manufacturing chip and the foundation of semiconductor industry.

As chips, reservoirs, and other applications in computer, communications, military, industrial medicine and other fields, its importance is self-evident.

early detection of cracks and microcracks has become very important in semiconductor production. If there is a crack in the fragile semiconductor material, it will lead to the breakage of a single solar cell, the shutdown of the production machine and the device, and the cleaning is very difficult.

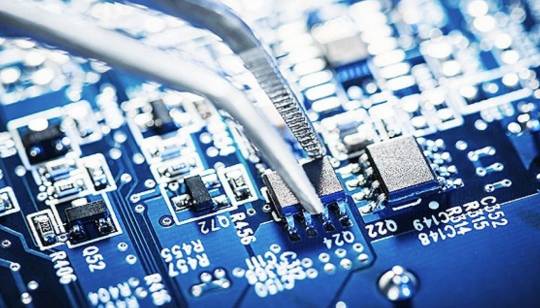

for failure analysis, the assembled ic must be subjected to crack or lithography detection. For example MEMS( microelectromechanical systems), the entire production process needs to be tested.

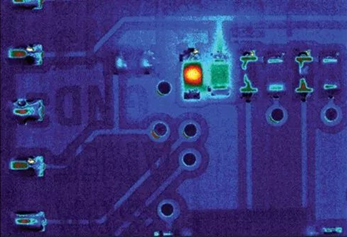

Infrared thermal imager can change the internal detection of semiconductor from "invisible" to "visible ". The distribution of "see" heat is less time-consuming and more accurate than detection by experience and intuition.

Infrared thermal imager is a kind of non-contact temperature measuring instrument. By receiving the surface temperature radiation signal of the object, the thermal image expressing the temperature distribution on the surface of the object can be obtained through internal treatment. After analysis, the defects of the object can be found. can detect temperature distribution, heat dissipation effect, energy consumption design, maintenance detection and so on in the semiconductor industry, and can also provide reference for the design layout of PCB plates.

For integrated circuits, traditional quality inspection and troubleshooting require rich experience and time-consuming. The thermal image of the circuit board can be obtained by using infrared thermal imager. By comparing with the thermal image of the normal circuit, the fault location can be found. Carry on accurate check.

With the rapid development of chip technology, the application of infrared thermal imager to detect chip production and quality inspection will be a very advanced and effective means.

Intelligent spectrum technology infrared thermal imager supports real-time, all-weather, accurate measurement function, supports alarm output, can link the existing monitoring system, and support customers to carry out secondary development, will be able to improve the semiconductor device production quality inspection efficiency and troubleshooting accuracy.It is divided into hand-held and fixed infrared thermal imager, which are used in different fields.

As an OEM, we can provide customers with professional and competitive infrared thermal imaging cameras, low light imaging and other multispectral thermal imaging products and industry solutions.

Go and contact with your sales consultant Cynthia WhatsApp:+86 18502742430 and get a discount today.